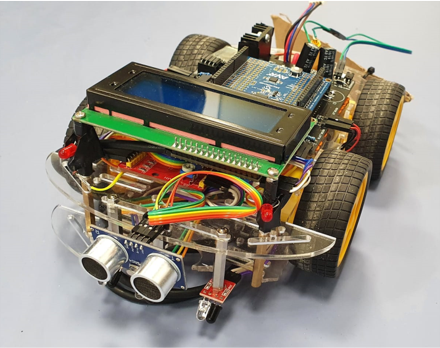

Etron-Icar Autonomous Robot Car

An autonomous robot car with multiple operation modes including line following, object avoidance, and remote control.

Grade: 8.9

Etron-Icar Autonomous Robot Car

The Etron-Icar project was developed as part of my Embedded Systems Engineering studies at HAN University. This autonomous robot car represents a comprehensive exploration into embedded systems, featuring multiple operation modes and advanced sensor integration. The project was completed in collaboration with team members Len Verploegen, Richard Kroesen, William van Barneveld, and Jochem Schouten.

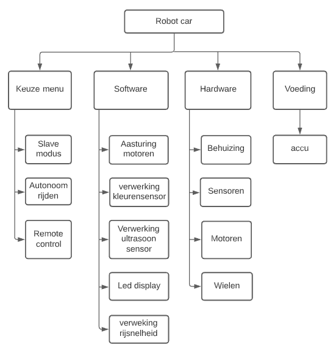

Project Overview

The Etron-Icar is designed to operate in three distinct modes: Manual Remote Control, Autonomous Navigation, and Slave Following. Each mode demonstrates different aspects of embedded system programming and sensor integration, making this a comprehensive learning experience in robotics and autonomous systems.

Key Features

- Three Operation Modes: Manual control via Bluetooth, autonomous line following with obstacle avoidance, and leader-following capability

- Advanced Sensor Suite: Ultrasonic distance sensors, infrared line sensors, and speed measurement sensors

- Real-time Display: 20x4 LCD showing speed, direction, operating time, and current mode

- Bluetooth Connectivity: Remote control via Android smartphone application

- Custom PCB Design: Integrated H-bridge motor control and power management

- Intelligent Navigation: Line following with object detection and avoidance algorithms

Technical Specifications

- Microcontroller: ATmega328P (Arduino-compatible)

- Programming Language: C with register-level HAL library

- Communication: Bluetooth HC-05 module at 9600 bps

- Power System: Dual power supply (Li-ion battery pack for motors, power bank for electronics)

- Motor Control: L293D H-bridge with PWM speed control

- Maximum Speed: 3.7 km/h

- Sensor Array: 3x IR line sensors, HC-SR04 ultrasonic sensor, optical speed sensor

Operation Modes

1. Manual Remote Control

The robot can be controlled remotely using a smartphone app via Bluetooth connection. Users have full control over:

- Forward and backward movement

- Left and right turning (90-degree precision)

- Variable speed control (10 levels)

- Real-time status monitoring

2. Autonomous Mode

In autonomous mode, the Etron-Icar demonstrates advanced robotics capabilities:

- Line Following: Uses three IR sensors to track a black line with high precision

- Obstacle Avoidance: Detects objects using ultrasonic sensors and navigates around them

- Path Recovery: Automatically returns to the line after obstacle avoidance

- Speed Adaptation: Adjusts speed based on path complexity and obstacles

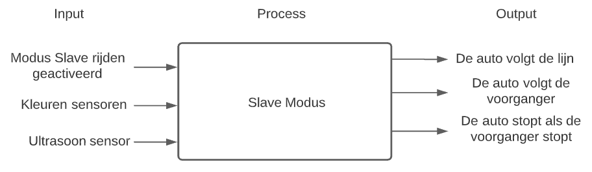

3. Slave Mode

The slave mode showcases advanced following algorithms:

- Leader Following: Maintains optimal distance (~30cm) from a lead vehicle

- Line Adherence: Continues following the line even when the leader deviates

- Automatic Stopping: Stops when the leader stops, resumes when movement detected

- Distance Control: Dynamic speed adjustment based on proximity to leader

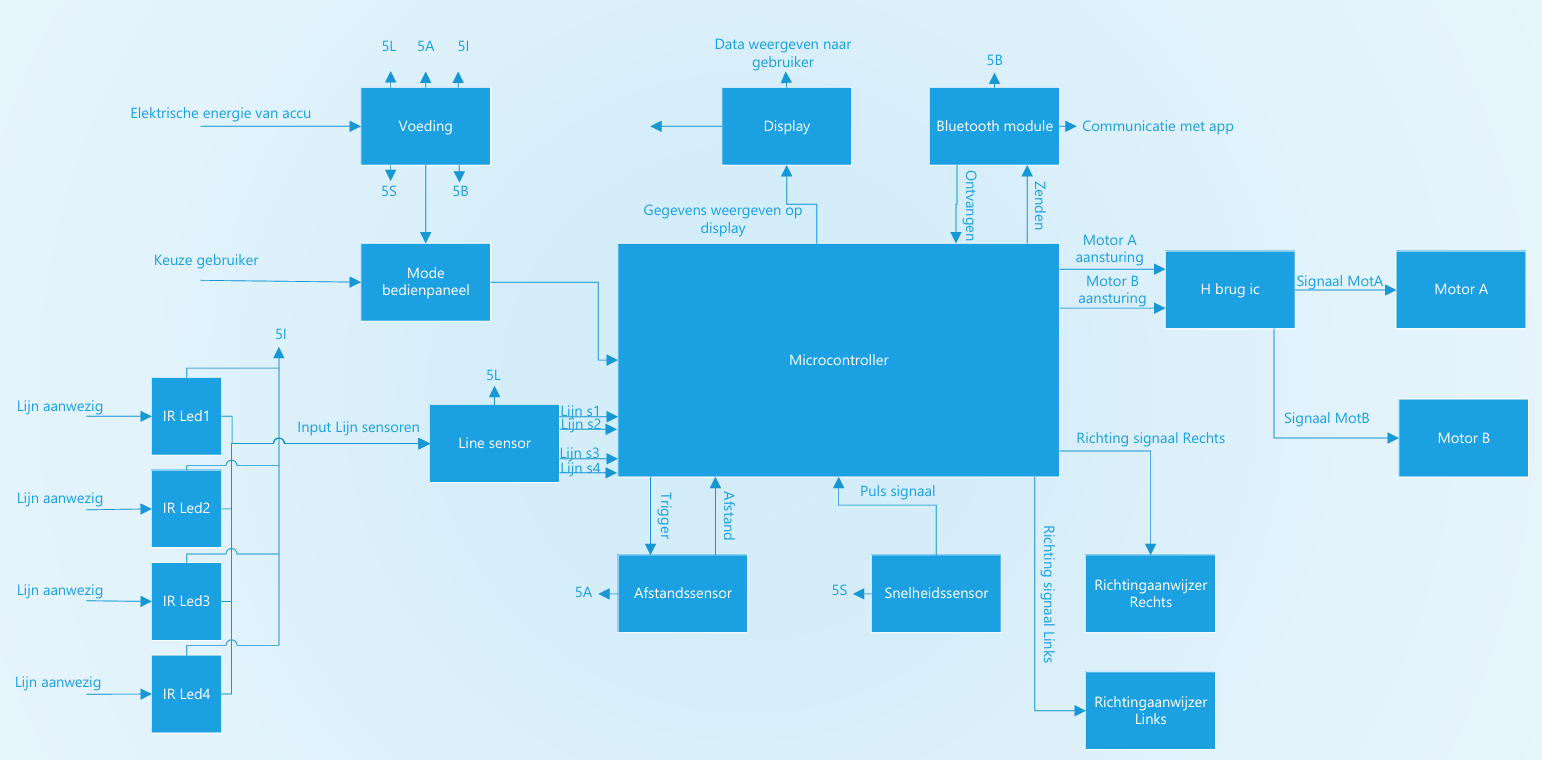

System Architecture

The system employs a hierarchical design approach:

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Main Controller (ATmega328P)

├── Sensor Subsystem

│ ├── Line Detection (3x IR sensors)

│ ├── Distance Measurement (HC-SR04)

│ └── Speed Monitoring (Optical sensor)

├── Motor Control Subsystem

│ ├── H-Bridge Driver (L293D)

│ ├── PWM Speed Control

│ └── Direction Control

├── Communication Subsystem

│ ├── Bluetooth Module (HC-05)

│ └── Serial Interface

└── User Interface Subsystem

├── LCD Display (20x4)

├── Mode Selection Button

└── Status LEDs

Implementation Highlights

Custom PCB Design

Rather than using breadboard connections, we designed a custom PCB featuring:

- Integrated H-bridge motor driver

- Voltage regulation (5V and 9V rails)

- Convenient header connections for all sensors

- Compact form factor fitting the robot chassis

Power Management

The dual power supply approach ensures system stability:

- Motor Power: 3x 18650 Li-ion batteries (11.1V) regulated to 9V

- Electronics Power: USB power bank providing stable 5V

- Current Capacity: Supports up to 1.2A peak motor current

Sensor Integration

Advanced sensor fusion techniques provide reliable navigation:

- Line Detection: Three-sensor array for precise line tracking

- Distance Measurement: Ultrasonic ranging with 2cm accuracy

- Speed Calculation: Optical encoder providing real-time velocity feedback

Software Architecture

The embedded software follows a modular design pattern:

Core Functions

- Motor Control: PWM-based speed control with directional logic

- Sensor Processing: Real-time sensor data acquisition and filtering

- Mode Management: State machine handling mode transitions

- Display Updates: Real-time status display with user interface

- Communication: Bluetooth command processing and response

Real-time Performance

- Control Loop: 50Hz main control loop for responsive behavior

- Sensor Sampling: 100Hz sensor reading for precise navigation

- Display Updates: 10Hz display refresh for smooth user experience

Testing and Validation

Comprehensive testing was conducted to validate all functional requirements:

System Testing Results

- Manual Control: ✅ Full directional control with variable speed

- Autonomous Navigation: ✅ Line following with obstacle avoidance

- Slave Mode: ✅ Leader following with distance maintenance

- Display Functions: ✅ Real-time data display and mode selection

- Bluetooth Communication: ✅ Reliable remote control operation

Performance Metrics

- Line Following Accuracy: 95% line retention under normal conditions

- Obstacle Avoidance: 100% success rate for standard test objects

- Speed Range: 0.3 - 3.7 km/h with smooth acceleration

- Battery Life: 15+ minutes of continuous operation

Technologies Used

- Programming: C with ATmega328P register-level programming

- Hardware Design: Custom PCB design using EasyEDA

- Mobile App: Android Bluetooth control application

- Development Tools: Arduino IDE, logic analyzer for debugging

- Documentation: Technical drawings, flowcharts, and system diagrams

Lessons Learned

This project provided valuable insights into embedded systems development:

- System Integration: Coordinating multiple subsystems requires careful planning

- Power Management: Dual power supplies improve system reliability

- Sensor Fusion: Multiple sensors provide redundancy and improved accuracy

- Real-time Programming: Timing constraints are critical in autonomous systems

- User Interface Design: Clear feedback improves user experience

Future Improvements

Potential enhancements for future iterations:

- Advanced Path Planning: Implementation of more sophisticated navigation algorithms

- Wireless Communication: WiFi connectivity for extended range control

- Computer Vision: Camera integration for enhanced obstacle detection

- Machine Learning: Adaptive behavior based on environmental conditions

Conclusion

The Etron-Icar project successfully demonstrates the integration of multiple embedded systems technologies into a cohesive autonomous vehicle platform. The project met all specified requirements and provided excellent hands-on experience with robotics, embedded programming, and system integration. The modular design approach and comprehensive testing ensure a robust and reliable system suitable for educational and demonstration purposes.

This project represents a significant milestone in my embedded systems engineering education, showcasing practical application of theoretical concepts in a real-world robotics platform.

This project was completed as part of the introductionary project (EMBSYP08-PRJ1) at HAN University of Applied Sciences, Embedded Systems Engineering program, S1 2021-2022.