Railway Signals Telemetry - Predictive Maintenance System

An embedded system for predictive maintenance of LED-based railway signaling systems using functional safety methodologies.

Grade: 8.0

Railway Signals Telemetry - Predictive Maintenance System

This project explores the implementation of functional safety methodologies. I had a idea for predictive maintenance of LED-based railway signaling systems. The objective was to develop an embedded monitoring system that could proactively address signal failures and enhance the reliability of railway operations in the Netherlands.

Problem Statement

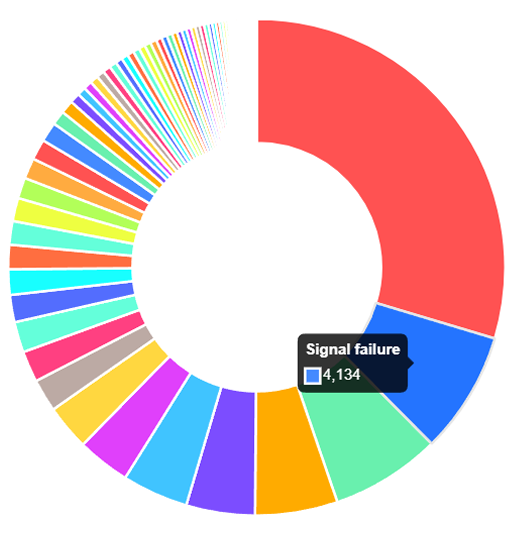

Signal failures represent the second largest contributor to railway traffic disturbances in the Netherlands. Between January 2024 and May 2024, there were 4,134 reported incidents attributed to signal failures out of 14,684 infrastructure-related disruptions. Each signal failure incident resulted in nearly 3 hours of downtime on average before resolution.

Statistical breakdown of railway disturbances showing signal failures as a major contributor

Statistical breakdown of railway disturbances showing signal failures as a major contributor

System Architecture

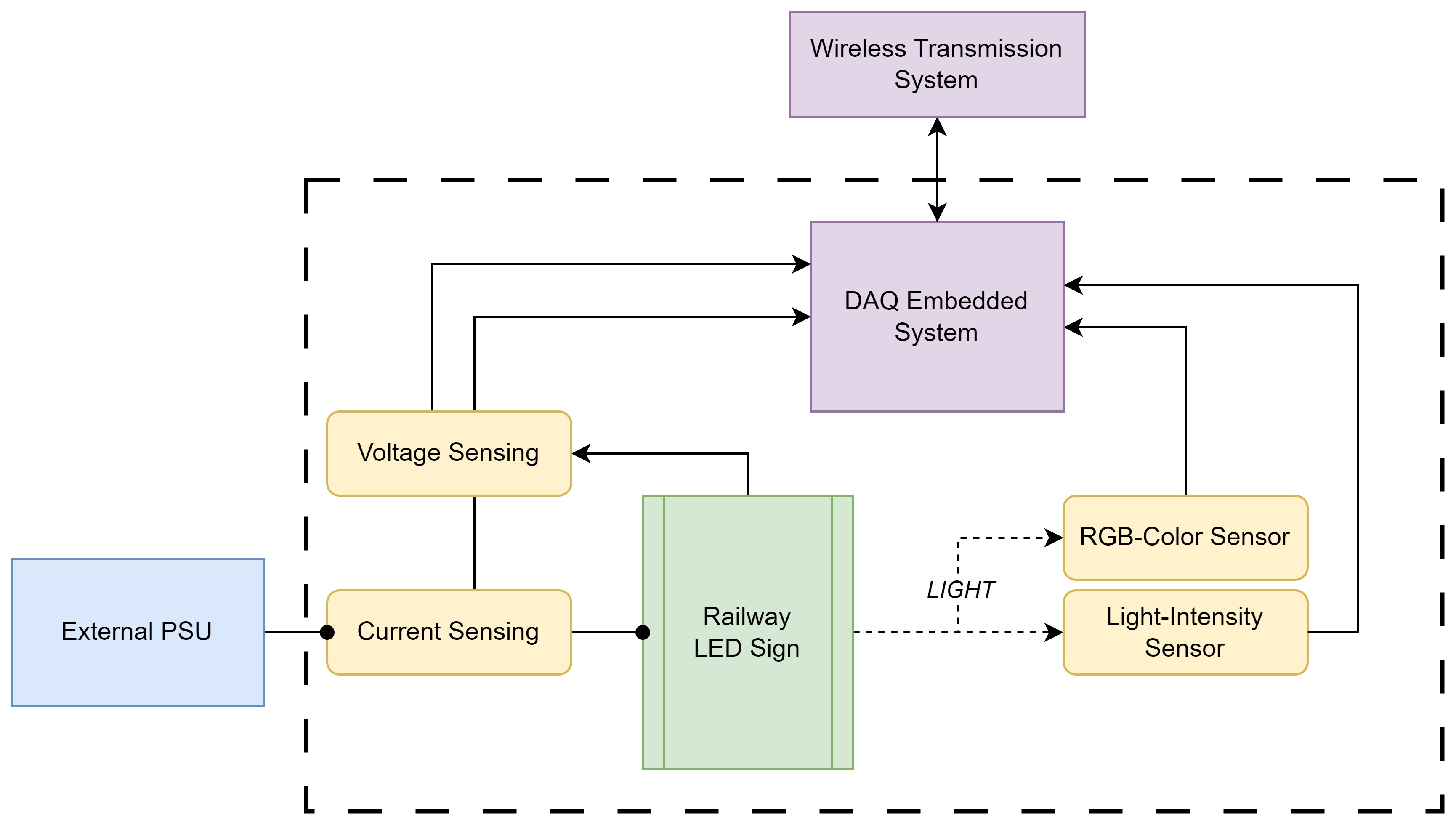

The proof-of-concept system was designed with functional safety as a core principle, incorporating multiple monitoring capabilities and fail-safe mechanisms.

High-level system design showing the main components and data flow

High-level system design showing the main components and data flow

Key Features

- RGB Color Recognition: Real-time monitoring of signal colors (red, green, yellow) to detect color shifting and degradation

- Light Intensity Monitoring: Continuous measurement of LED brightness to identify dimming over time

- Power Consumption Analysis: Tracking energy usage patterns to detect potential LED driver issues

- Junction Temperature Monitoring: Measuring LED temperature to assess thermal stress and predict failure

- Functional Safety Implementation: Dual watchdog timers, brown-out reset, and centralized error handling

- Real-Time Data Logging: UART-based data transmission for continuous monitoring and analysis

- RTOS Integration: FreeRTOS implementation for deterministic task scheduling and resource management

Technical Implementation

The system was built around an STM32F03 microcontroller chosen for its functional safety features and reliability in safety-critical applications.

Functional Safety Features

- Dual Watchdog System:

- Independent Watchdog (IWDG) clocked by LSI oscillator

- Window Watchdog (WWDG) clocked by system clock

- Power Supply Monitoring:

- Brown-out Reset (BOR) for power failure detection

- Power-on Reset (POR) for proper system initialization

- Error Handling: Centralized error management system for consistent fault response

Data Collection Methods

The system monitors several key performance indicators:

- Raw RGB Color Values: Precise color measurement for signal accuracy verification

- Light Intensity: Brightness measurements for visibility assessment

- Power Consumption: Current and voltage monitoring over time

- Sampling Rate: Configurable measurement frequency (tested at 340 samples/sec)

Results and Findings

The proof-of-concept successfully demonstrated the feasibility of LED health monitoring for railway signals. Initial testing showed:

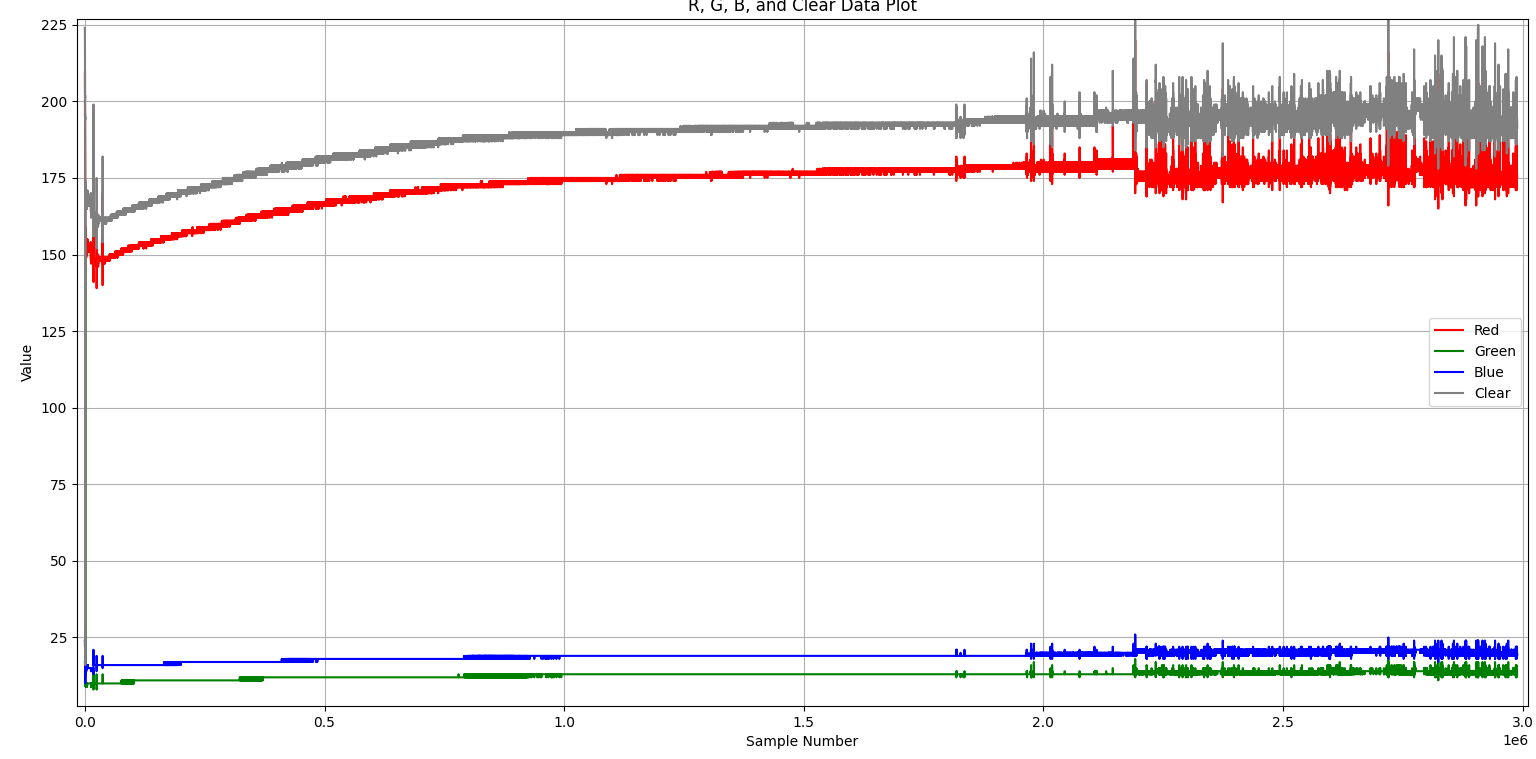

3-hour experimental measurement showing LED intensity variations over time

3-hour experimental measurement showing LED intensity variations over time

- Successful Color Differentiation: Clear distinction between red, green, and blue signal states

- Stable Data Collection: Consistent readings over extended periods

- Real-Time Monitoring: Effective UART-based data transmission to external analysis systems

- Functional Safety Operation: Reliable watchdog operation and error handling

Technologies Used

- Programming Language: C with STM32 HAL library

- Real-Time OS: FreeRTOS for task management and scheduling

- Hardware: STM32F03 microcontroller with functional safety features

- Communication: UART protocol for data transmission

- Data Format: CSV logging for analysis compatibility

- Development Tools: STM32CubeIDE, ST-LINK debugger

- Standards Compliance: EN50129, IEC 62425, MISRA C guidelines

Applications and Impact

This system addresses critical challenges in railway infrastructure:

Dutch Railway Context

- Signal Types: Monitoring of standard 3-light systems (green, red, yellow)

- Operational States: Detection of various signal conditions including blinking patterns

- Safety Standards: Compliance with Dutch railway regulations and international standards

- Future Compatibility: Relevance for ERTMS Level 2 transition and road traffic applications

Predictive Maintenance Benefits

- Proactive Fault Detection: Early identification of LED degradation before failure

- Reduced Downtime: Minimizing the 3-hour average resolution time for signal failures

- Cost Efficiency: Preventive maintenance scheduling to reduce emergency repairs

- Safety Enhancement: Improved reliability of safety-critical signaling systems

Future Enhancements

The project identified several areas for continued development:

Technical Improvements:

- Machine learning algorithms for predictive analysis

- Enhanced spectral analysis capabilities

- Wireless data transmission options

- Integration with existing railway management systems

Functional Safety Enhancements:

- CRC error detection and packet-based protocols

- DMA implementation for reduced CPU load

- Low power mode optimization

- Extended environmental testing

Conclusion

This proof-of-concept demonstrates the viability of using embedded systems with functional safety methodologies for railway signal monitoring. The system successfully integrates color recognition, real-time data transmission, and safety features, providing a foundation for enhanced railway signal reliability and maintenance practices.

The potential impact on railway operations is significant, with the possibility of reducing the 4,134 annual signal failures and associated downtime. Further development and field testing could lead to a comprehensive solution for railway signaling technology advancement.

This project was completed as part of the Microcontrollers 6 - Functional Safety (EMBSYS01-FS) course at HAN University of Applied Sciences, Embedded Systems Engineering program, S6 2023-2024.